Chiller Monitor

The Smarter way to

MAKE BETTER BEER™

Remotely monitor your chiller’s performance.

Anytime, Anywhere

Any brewer will tell you that your tank cooling system is one of the most important pieces of equipment in the brewery for producing consistent, quality beer. It’s vital to the knockout, fermentation, clarification and packaging processes. Chances are, the last time you thought about your chiller was the last time there was a problem with your cooling system. Having a watchdog on such a vital system should be a standard operating procedure. Do you know how hard your chiller is working? Are all the operational parameters within normal bounds? Make sure you know about chiller issue before it affects your production.

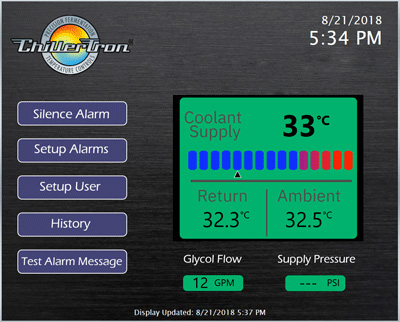

Chiller Monitor by ChillerTron is an early warning and monitoring system that sends alert notifications directly to your phone and email for coolant system problem conditions.

- See how hard your chiller is working with +/- 0.5C temperature sensors for coolant supply, return and ambient (air) temperature

- Verify your pump is circulating and guard against leaks with flow detection and 0-30 psi pressure sensor

- Reservoir Level alarm to warn when fluid levels get too low to protect the heat exchanger

- Web interface allows you to login from any internet enabled device

- History graphs show what your chiller has been doing

- Manage users contact info and duty hours, set alarm parameters to make sure you know about coolant system issues before they disrupt your production

Protect your chiller and your production

Just apply power, plug in internet, and sign into the website to get started with a factory installed Chiller Monitor in your G&D or Tanktemp chiller. Field installation requires sensors be mounted in chiller or coolant piping. Just a $25/month subscription allows all users in your organization 24/7 access to data and alarms.

Specifications:

- Pressure sensor: 0-30 psi

- Flow switch: 12 gpm

- Temperature sensors: 3 digital +/- 0.5c

- Data Connection: CAT5 Ethernet

- Power 120-240 VAC

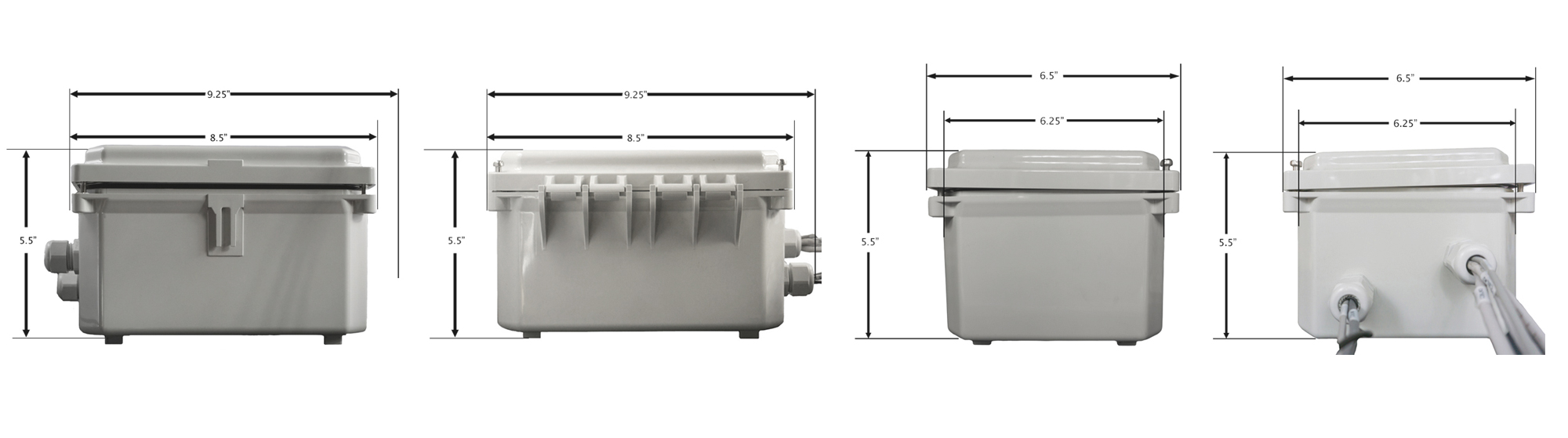

- Enclosure: Nema 4X rated electrical enclosure

- Alerts: SMS text and Email

- Alarm thresholds and trigger times: User programmable